Production

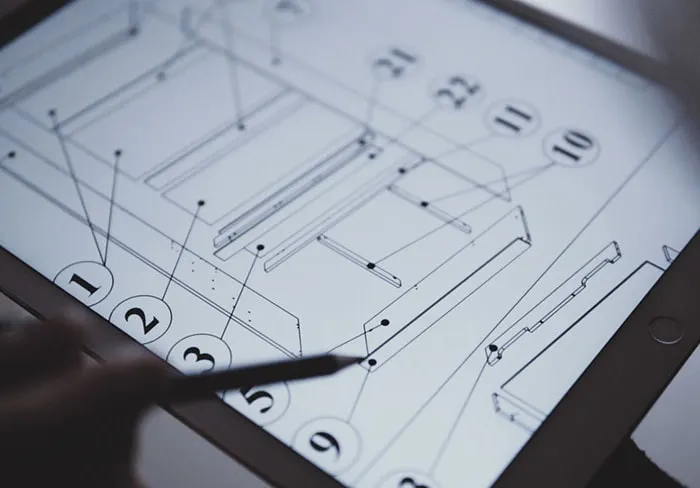

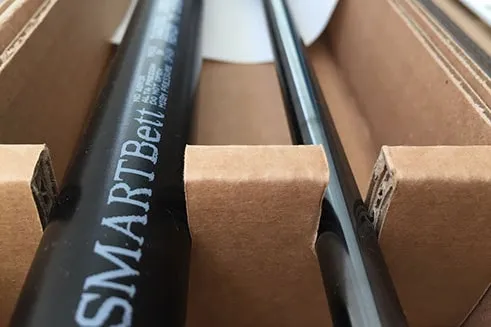

The SMARTBett® also holds the second glance! There are many sophisticated components that have highly qualified employees of our development teams with great care, attention to detail and always designed and implemented with the view of the whole - a unique fold away bed. These details contribute significantly to the extraordinary functionality of this innovative designer furniture. The materials used in each case, are the optimal solution in terms of stability and lightness, compactness and comfort as well as functionality and design.

Wishlist

Wishlist